Multi head scale weighing vertical large packaging machine,15-35

/min,Particles, Irregular items that

Process flow:

Manually pouring a single material into the vibrating feeder

storage hopper of the elevator - Automatic feeding - Lifting to the

feeding hopper of the combined scale - Weighing by the combined

scale - Unqualified removal - Qualified discharge to the hopper of

the packaging machine - Packaging machine receives the discharge

signal - Automatic bag making and coding - Automatic sealing -

Finished product falls onto the output conveyor belt

Technical parameters:

Packaging materials: particles, tablets, or irregularly weighted

items

Packaging capacity: 100-2000g

Packaging speed: 20-40bags/min (depending on the length of the

packaging bag and material conditions)

Bag making capacity: 115 ≤ W ≤ 350mm x L ≤ 310mm (one bag pulling)

Packaging film: ≤ 750mm

Bag size: TBD

Packaging film width: to be determined

Sealing form: back sealing

Vertical sealing form: side sealing (single action)

Back sealing width: 10-15mm straight grain

Horizontal sealing width: The entire width of the horizontal

sealing mold is 20mm, with straight lines (spacing of 2mm)

Cutting method: serrated cutting (transverse sealing with a knife

in the middle, non independent cutting)

Optoelectronic control: color code control length or touch screen

setting length

Bag pulling method: servo motor drives belt to pull the bag

Horizontal sealing method: pneumatic horizontal sealing

Packaging materials: composite packaging materials

Power supply: AC 220V/50HZ 4.5KW

Gas source pressure: 6Kg

Gas consumption: 0.6 m3/min

Basic configuration:

7 'Inovance color touch screen+Inovance PLC (Chinese operating

language), with error prompt and self-diagnosis function

Taiwan AIRTAC pneumatic components

Yudian temperature control (1 longitudinal seal, 2 transverse

seals)

Inovance servo motor bag pulling

Schneider or OMRON electrical components

The exposed parts of the entire machine are made of 304 stainless

steel or aluminum alloy material (excluding moving parts)

The part in contact with the material is made of stainless steel

304 material

Schematic diagram of combined scale:

Technical parameters of the combined scale:

HX-A14 14 head 1.6L stainless steel waterproof microcomputer

combination scale

Technical parameters:

Weighing range: 100-2000g

Weighing speed: ≤ 60bags/min (varies depending on packaging weight

and material characteristics)

Weighing accuracy range: X (0.5) level, approximately ± 0.5-2g

(depending on the material situation)

Hopper capacity: 1600ml

Main vibration plate: vibrating type

Driving method: stepper motor

Body material: 304 stainless steel

Scale hopper material: 304 flat stainless steel

Power supply power: AC 220V/50HZ 2.5KW/16A

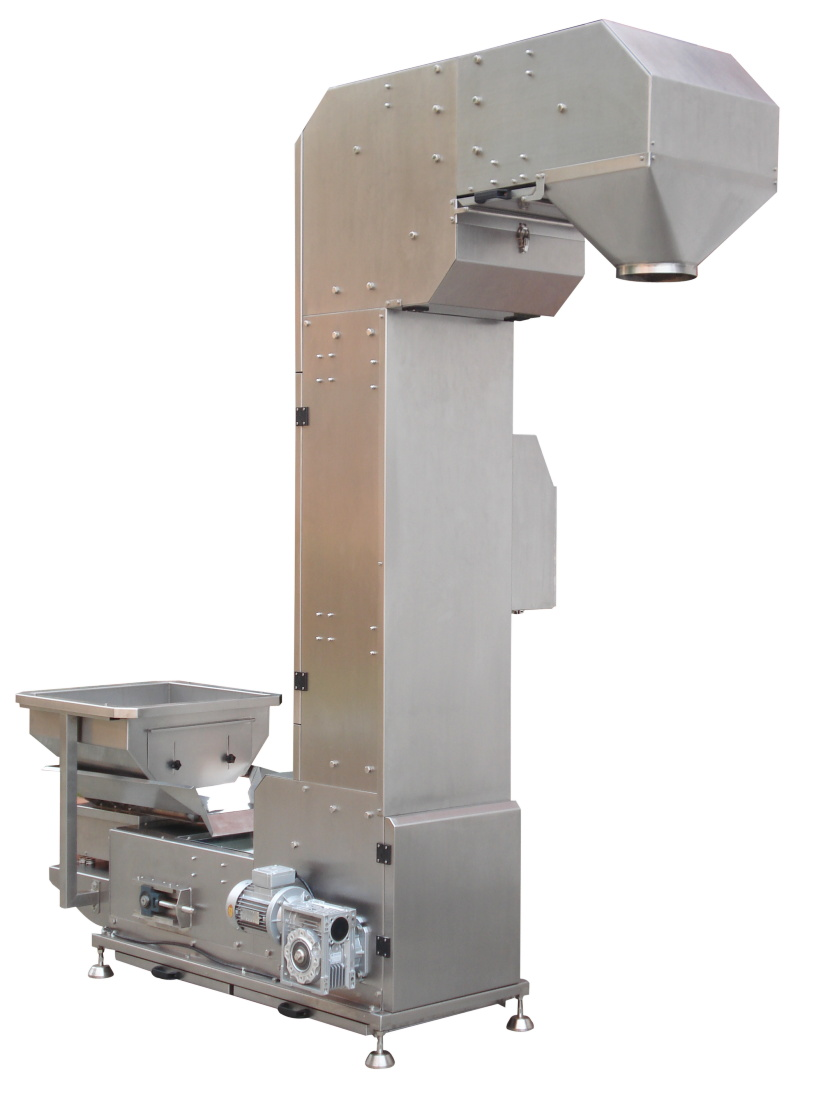

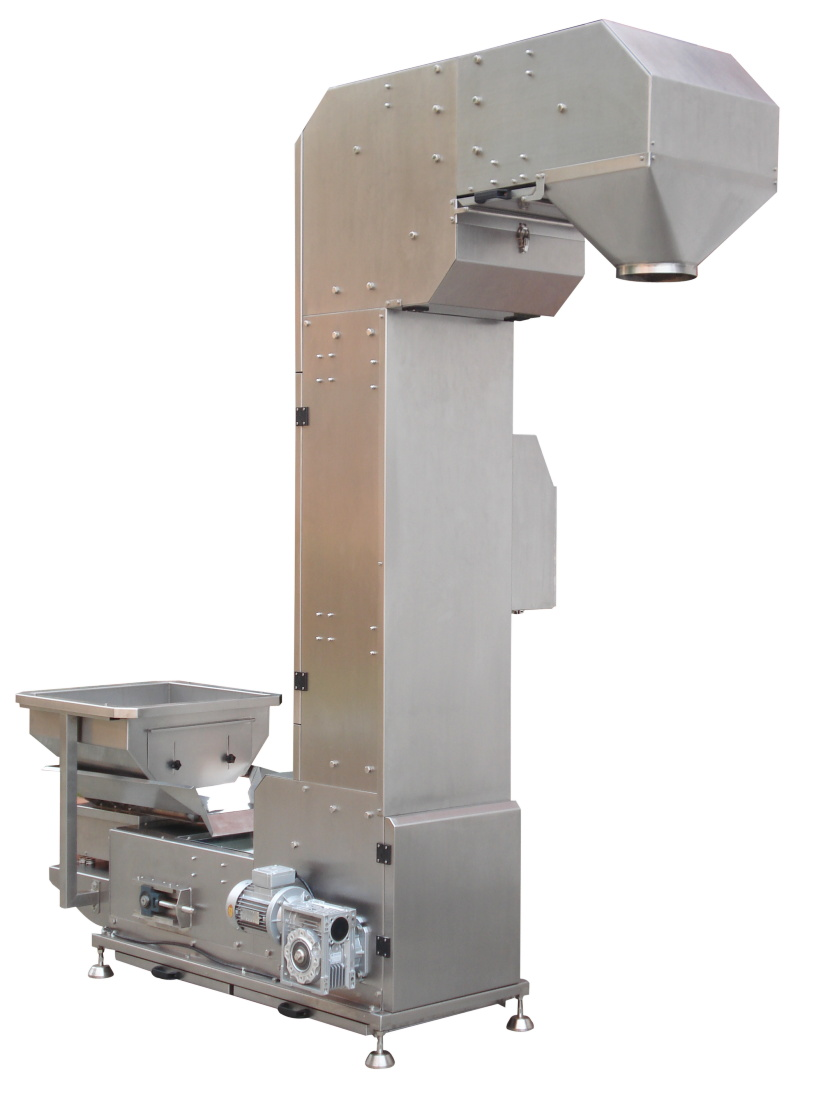

Schematic diagram of CST-D10-3600 Z-type bucket material elevator

(Type 304):

Technical parameters:

Conveying capacity: 0-10 cubic meters per hour (calculated based on

a loading coefficient of 0.5)

Outlet height: 3600mm (depending on equipment height)

Sprocket and sprocket shaft: nickel plated

Chain: 304 stainless steel

Lift bucket material: PP, full capacity 2.2L

Vibration slot size: 1000L x 280W x 100H

Bracket material: ordinary steel spray plastic, material of

material hopper: 304 stainless steel

Hopper volume: 60L

Control: Equipped with a control box, variable frequency speed

regulation, including a capacitor level device

Power supply power: single-phase 220V 50Hz 750W

Overall weight: 200kg

Including chip removal function (equipped with magnetic rod and

sediment vibrator) and dust screening and non screening: Iron

removal refers to the absorption of iron containing objects onto

the iron rod when the feeding hopper comes out. The baffle can be

replaced, and those without holes are used for packaging fine

materials (such as small fruits). The baffle with holes can filter

out fine dust.

Display diagram of heat transfer printing intelligent coding

machine: